SJT308

Hits:98

ER308

TIG Wire for Stainless Steel: ST308

Specification:AWS A5.9 ER308

ISO 14343-B: SS308

GB/T 29713 S308

Introduction:

-

ST308 is a kind of TIG welding wire for 21Cr-10Ni austenitic stainless steel. Used in the welding of similar base materials, equipment and machine parts.

-

Stable arc and low spatter, and the deposited metal has excellent corrosion resistance.

Application:

-

Petrochemical Industry

-

Food processing equipment

-

Medical equipment

Pass the certification:

Contact Us

Chemical Composition of Wire %

| C | Mn | Si | Cr | S | P | Ni | Mo | |

| AWS | ≤0.08 | 1.0-2.5 | 0.30-0.65 | 19.5-22.0 | ≤0.03 | ≤0.03 | 9.0-11.0 | ≤0.75 |

| TR(HC) | 0.045 | 1.76 | 0.30 | 20.0 | 0.006 | 0.02 | 9.64 | 0.05 |

Mechanical Properties of Deposited Metal:

| Tensile Strength | Yield Strength | Elongation | ||||

| Mpa | Mpa | % | ||||

| TR(HC) | 550 | 320 | 35 | |||

Packing and Recommended Parameters:(DC-)

| Diameter | Current Range(Amp) | Tube-1000mm | |

| mm/in | E.H | OH.V | 5kg (11 lbs) |

| 1.6(1/16) | 50-100 | 50-100 | √ |

| 2.0(5/64) | 100-200 | 100-200 | √ |

| 2.4(3/32) | 200-300 | 200-300 | √ |

| 3.2(1/8) | 300-400 | 300-400 | √ |

| 4.0(5/32) | 400-500 | 400-500 | √ |

-

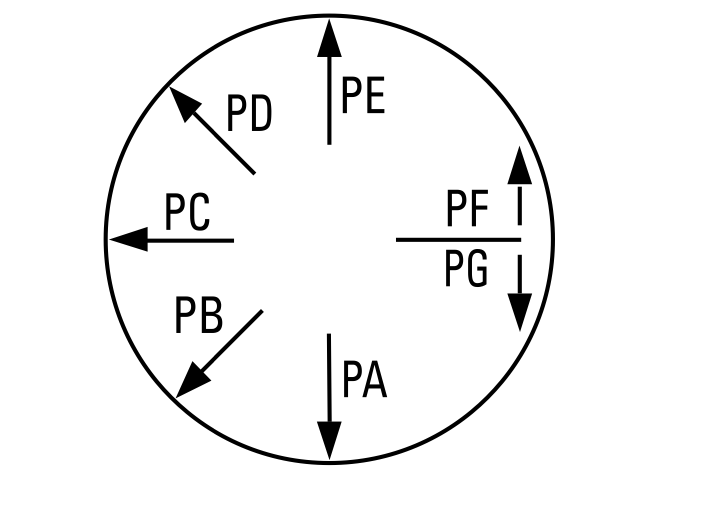

Welding position:

-

Shielding Gas:

Ar

-

Attention:

1. Tungsten electrode extension length: 3~5mm.

2. Arc length: 1-3mm.

3. Argon gas flow rate: 10~18L/min.

4. Remove rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号