SJ5356

Hits:42

ER 5356

Aluminium Welding Wire: ER 5356

Specification:AWS A5.10 ER5356

ASME A5.10 ER5356

GB/T10858 S AI 5356

ISO 18273 S AI 5356(AIMg5Cr)

Introduction:

ER5356 is a Aluminum alloy welding wire containing about 4.5% magnesium, with good seawater corrosion resistance, and high fracture toughness and other characteristics.

Suitable for welding parts 5000 series, 6000 series, 7000 series bearing structural parts: Such as 5083,6061,6063,5086,7005,7039, etc.

Application:

ships

offshore facilities

low-temperature workshops

pressure vessels

rail transit

automotive industries

Pass the certification:

Contact Us

Chemical Composition of Wire % :

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be | Other | Al | |

| TR(HC) | ≤0.40 | ≤0.40 | ≤0.10 | 0.5-1.0 | 4.3-5.2 | 0.05-0.25 | ≤0.25 | ≤0.15 | ≤0.0003 | ≤0.10 | Rem |

Typical Characteristics:

| Melting Temperature | Specific Conductance | Density | Corrosion Resistance | Thermal Expansivity | Thermal Conductivity |

| 1075-1180℉ | 16-19Ω.m/mm² | 2.66g/mm³ | A(Gen)A(sCC) | 23.7x106/K | 110-120W/m.k |

Mechanical Properties Of Typical Welded Joints(For Reference):

| Motherboard | Motherboard Performance | Property of Joint | ||||

| Rm(Mpa) | Rp0.2(Mpa) | AI% | Rm(Mpa) | Rp0.2(Mpa) | AI% | |

| 6061-T6/T651 | 310 | 275 | 12 | 205 | 130 | 11 |

| 6063-T6 | 240 | 210 | 12 | 135 | 80 | 12 |

| 7005-T6/T63 | 370 | 315 | 12 | 315 | 205 | 10 |

| 7039-T64 | 445 | 380 | 13 | 300 | 170 | 13 |

| 5086-H32 | 290 | 205 | 12 | 265 | 115 | 17 |

| 5083-O | 310 | 200 | 16 | 275 | 120 | 15 |

| 6082-T6 | 310 | 275 | 11 | 210 | 130 | 10 |

Diameter/Packing:

| Diameter | MIG | TIG-1000mm | Coil | Drum | ||||||||

| mm/in | 0.5Kg(1.1lbs) | 2Kg(4.4lbs) | 5kg(11lbs) | 6kg(13.2lbs) | 7kg(15.4lbs) | 9kg(19.8lbs) | 5kg(11lbs) | 10kg(22lbs) | 20kg(44lbs) | 8~15Kg(17.6lbs-33lbs) | 80Kg(176lbs) | 100Kg(220lbs) |

| 0.8(0.030) | √ | √ | √ | √ | √ | √ | ||||||

| 0.9(0.035) | √ | √ | √ | √ | √ | √ | ||||||

| 1.0(0.040) | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 1.2(0.045) | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| 1.6(1/16) | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |

| 2.0(5/64) | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||

| 2.4(3/32) | √ | √ | √ | √ | ||||||||

| 3.0(0.117) | √ | √ | √ | √ | ||||||||

| 3.2(1/18) | √ | √ | √ | √ | ||||||||

| 4.0(5/32) | √ | √ | √ | √ | ||||||||

| 5.0(0.197) | √ | √ | √ | |||||||||

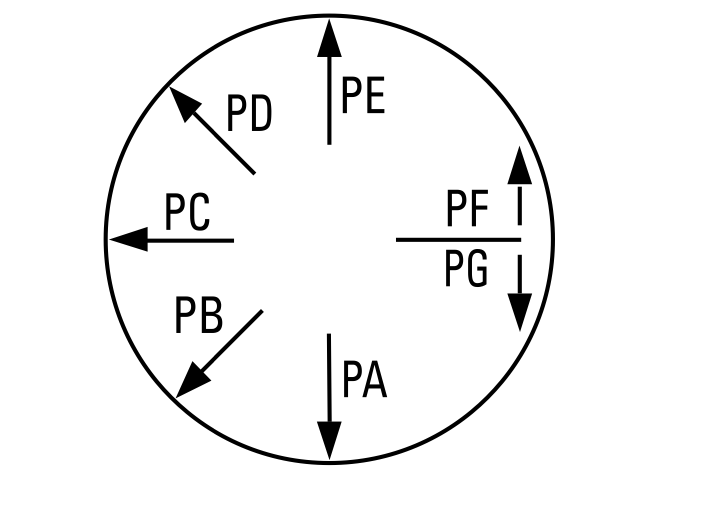

Welding position:

Shielding Gas:

Ar

Polarity:

DC pulse

苏公网安备 32058202010273号

苏公网安备 32058202010273号