SJ-50Y

Hits:124

G4Si1

Low Carbon and High Strength Steel SJ-50Y

Specification:AWS A5.18 ER70S-G

ISO 14341-A-G 424 C14Si1

GB/T8110-2020 ER50-G

DIN8559 SG3

Introduction:

Wide range of applications: suitable for welding low-carbon steel, low-alloy steel, and some medium-strength structural steel.

Good resistance to porosity: the addition of silicon and manganese helps reduce porosity defects in the weld.

Smooth feeding, stable arc, and beautiful weld bead appearance, low spatter,has excellent welding performance.

The deposited metal has good mechanical properties.

Application:

Automobiles

Shipbulding

Bridges

Constructions

Machinery

Pass the certification:

JIS、 CE

Chemical Composition of Wire %

| C | Mn | Si | P | S | Cu | Ni | Cr | Ti+Zr | |

| AWS | 0.06-0.13 | 1.60-1.90 | 0.80-1.20 | ≤0.025 | ≤0.025 | ≤0.30 | ≤0.15 | ≤0.15 | ≤0.15 |

| TR(HC) | 0.09 | 1.68 | 0.95 | 0.014 | 0.013 | 0.11 | 0.01 | 0.03 | 0.02 |

Mechanical Properties of Deposited Metal

| Tensile Strength | Yield Strength | Elongation | Impact Value | |||||

| Mpa | Mpa | % | -40℃ J | |||||

| TR(HC) | 589 | 465 | 25 | 80 | ||||

Packing and Recommended Parameters:(DC+)

| Diameter | Spool | Drum | ||||||

| mm/in | Current range(A) | 0.9kg(2 lbs) | 5kg (11 lbs) | 15kg(33 lbs) | 20kg(44 lbs) | 250kg(551 lbs) | 350kg(771lbs) | 400kg(881 lbs) |

| 0.6(0.023) | 80-180 | √ | √ | √ | √ | |||

| 0.8(0.030) | 80-220 | √ | √ | √ | √ | |||

| 0.9(0.035) | 80-220 | √ | √ | √ | √ | |||

| 1.0(0.040) | 100-250 | √ | √ | √ | √ | √ | ||

| 1.2(0.045) | 140-350 | √ | √ | √ | √ | √ | ||

| 1.4(0.052) | 180-370 | √ | √ | √ | √ | √ | √ | |

| 1.6(1/16) | 200-400 | √ | √ | √ | √ | √ | ||

| 2.0(5/64) | 200-500 | √ | √ | √ | √ | |||

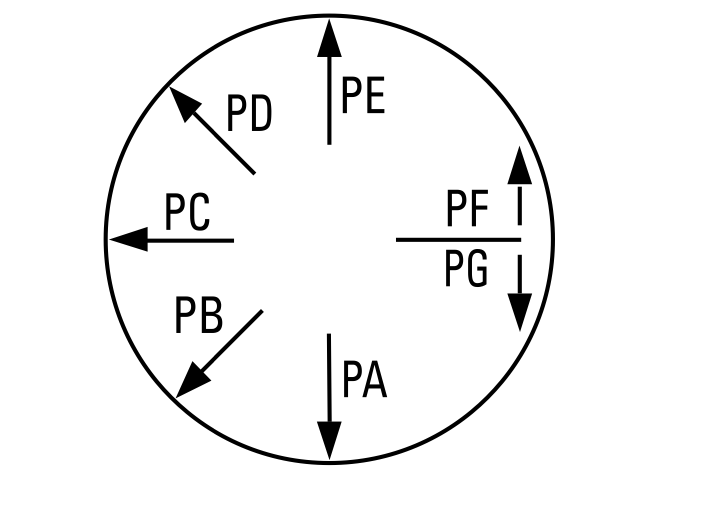

Welding position:

Shielding Gas:

75%~80%Ar+CO₂

or:

CO₂

Points for Attention:

1.Gas Flow Rate: 20~25 L/min.

2.Contact Tip-to-Work Distance (CTWD): 15~25 mm.

3.Removal of rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号