TIG SJ-53

Hits:116

ER70S-3

Low Carbon and High Strength Steel-TIG SJ-53

Specification:AWS A5.18 ER70S-3

IS0 636-A-W 38 3 2Si

GB/T8110-2008 ER50-3

Introduction:

Suitable for 500Mpa grade carbon steel and low alloy steel.

With appropriate addition of Ti, Zr and Al, which reduces the formation of oxides during welding and reduces porosity, cracks.

Smooth feeding, stable arc, and beautiful weld bead appearance, low spatter,has excellent welding performance.

The deposited metal has good mechanical properties.

Application:

Bridges

Vehicles

Shipbulding

Pressure Vessels

Pass the certification:

Contact Us

Chemical Composition of Wire %

| C | Mn | Si | P | S | Cu | Ni | Al | Ti+Zr | Mo | Cr | V | |

| AWS | 0.06-0.14 | 0.90-1.30 | 0.50-0.80 | ≤0.025 | ≤0.025 | ≤0.35 | ≤0.15 | ≤0.02 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 |

| TR(HC) | 0.07 | 1.13 | 0.57 | 0.015 | 0.011 | 0.08 | 0.10 | 0.003 | 0.020 | 0.01 | 0.030 | 0.001 |

Mechanical Properties of Deposited Metal

| Tensile Strength | Yield Strength | Elongation | Impact Value | |||||

| Mpa | Mpa | % | -30℃ J | |||||

| TR(HC) | 562 | 446 | 29 | 118 | ||||

Diameter/Packing

| Diameter | Tube-1000mm |

| mm/in | 5kg (11 lbs) |

| 1.6(0.063) | √ |

| 2.0(0.079) | √ |

| 2.4(0.095) | √ |

| 3.2(0.126) | √ |

| 4.0(0.165) | √ |

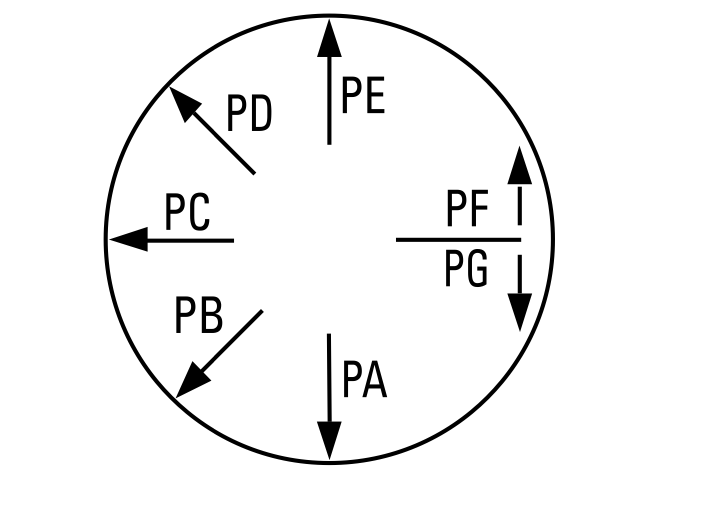

Welding position:

Shielding Gas:

Ar

Polarity:

DC-

Points for Attention:

1. Pure Ar > 99.99%.

2. 50-200A, protective gas 5-15L/min,200-350A, protective gas 12-20L/min.

3. Remove the rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号