TIG SJ-09CrCuSb

Hits:90

ER70S-G

Weathering Resistant Steel TIG SJ-09CrCuSb

Specification:AWS A5.28 ER70S-G

NB/T 47018.3-2017

GB/T 150.2

Introduction:

For 500Mpa grade steel,a sulfuric acid corrosion resistant TIG welding wire.

High crack resistance and strong sulfuric acid dew point corrosion resistance.

Excellent welding performance with smooth feeding, stable arc, neat welds, low spatter.

Suitable for welded structures such as air preheaters and heat exchangers operating in high-sulfur gas environments.

Application:

Electric power

Petrochemical

Metallurgy

Pass the certification:

Contact us

Chemical Composition of Wire %

| C | Mn | Si | P | S | Cu | Ni | Sb | Cr | Mo | Sn | V | Pb | As | Bi | |

| AWS | ≤0.12 | 0.35-0.65 | 0.20-0.40 | ≤0.025 | ≤0.015 | 0.25-0.45 | - | 0.04-0.10 | 0.70-1.10 | - | - | - | - | - | - |

| TR(HC) | 0.08 | 0.48 | 0.29 | 0.013 | 0.007 | 0.30 | 0.10 | 0.07 | 0.90 | 0.02 | 0.002 | 0.002 | 0.002 | 0.002 | 0.002 |

Mechanical Properties of Deposited Metal

| Tensile Strength | Yield Strength | Elongation | Impact Value | |||||

| Mpa | Mpa | % | -20℃ J | |||||

| TR(HC) | 552 | 448 | 28 | 115 | ||||

Diameter/Packing

| Diameter | Tube-1000mm |

| mm/in | 5kg (11 lbs) |

| 1.6(0.063) | √ |

| 2.0(0.079) | √ |

| 2.4(0.095) | √ |

| 3.2(0.126) | √ |

| 4.0(0.165) | √ |

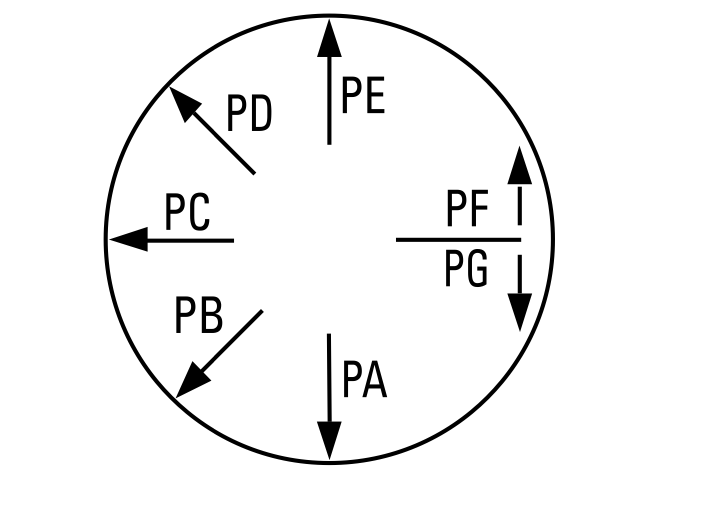

Welding position:

Shielding Gas:

Ar

Polarity:

DC-

Points for Attention:

1. Pure Ar > 99.99%.

2. 50-200A, protective gas 5-15L/min,200-350A, protective gas 12-20L/min.

3. Remove the rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号