TIG SJ-2CM

Hits:36

ER90S-B3

Heat-resistant steel TIG SJ-2CM

Specification:AWS A5.28 ER90S-B3

ASME/SFA-5.28 ER90S-B3

ISO 21952-B W 62 2C1M

GB/T 8110 ER62-B3

GB/T 39279-2020 W62I12C1M

NB/T 47018.3-2017

Introduction:

TIG welding wire for 620Mpa grade heat resistant steel.

For 2.25%Cr-1%Mo steel in high temperature envoirment,working temperature below 520℃.

Excellent welding performance with smooth feeding, stable arc, neat welds, low spatter.

Application:

high-temperature pipelines

pressure vessels

petrochemical equipment

Pass the certification:

Contact us

Chemical Composition of Wire %

| C | Mn | Si | P | S | Cu | Mo | Cr | Ni | |

| AWS | 0.07-0.12 | 0.40-0.70 | 0.40-0.70 | ≤0.025 | ≤0.025 | ≤0.35 | 0.90-1.20 | 2.30-2.70 | ≤0.20 |

| TR(HC) | 0.10 | 0.52 | 0.60 | 0.013 | 0.003 | 0.06 | 1.01 | 2.61 | 0.023 |

Mechanical Properties of Deposited Metal

| Tensile Strength | Yield Strength | Elongation | Impact Value | PWHT | |||||

| Mpa | Mpa | % | 0℃ J | ℃xh | |||||

| TR(HC) | 673 | 598 | 26 | -- | 690 x 1 | ||||

Diameter/Packing

| Diameter | Tube-1000mm |

| mm/in | 5kg (11 lbs) |

| 1.6(0.063) | √ |

| 2.0(0.079) | √ |

| 2.4(0.095) | √ |

| 3.2(0.126) | √ |

| 4.0(0.165) | √ |

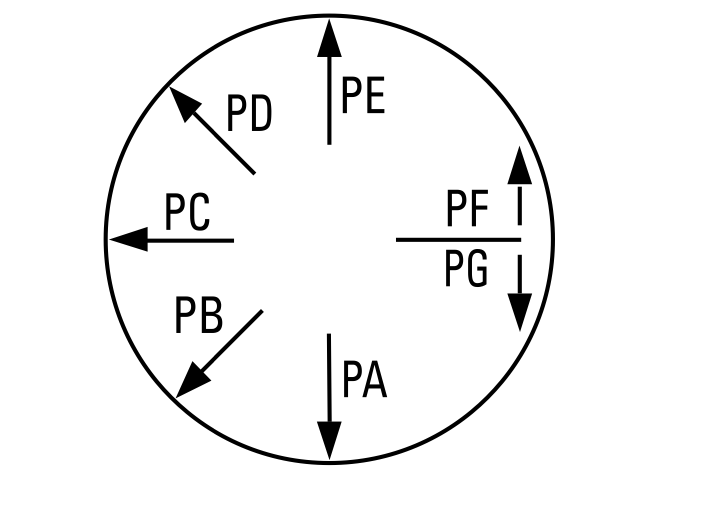

Welding position:

Shielding Gas:

Ar

Polarity:

DC-

Points for Attention:

1. Pure Ar > 99.99%.

2. 50-200A, protective gas 5-15L/min,200-350A, protective gas 12-20L/min.

3. Preheating and interpass temperature: 185-205 ℃;

4. Remove the rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号