SJ-18

Hits:109

YGW18

Low Alloy High Strength Steel SJ-18

Specification:JIS Z3312 YGW18

Introduction:

Used in high-strength steel structure welding, use a wide range of current with stable arc characteristics.

At the highest limit of the Japanese standard JASS 6 (40KJ/ cm.350°C), good metal strength and toughness can be maintained.

Application:

Bridges

High-rise buildings

Pass the certification:

JIS

Chemical Composition of Wire %

| C | Mn | Si | P | S | Cu | Ti+Zr | Mo | |

| AWS | ≤0.15 | 1.40-2.60 | 0.55-1.10 | ≤0.030 | ≤0.50 | ≤0.50 | ≤0.30 | ≤0.40 |

| TR(HC) | 0.07 | 1.80 | 0.76 | 0.011 | 0.13 | 0.13 | 0.16 | 0.22 |

Mechanical Properties of Deposited Metal

| Tensile Strength | Yield Strength | Elongation | Impact Value | |||||

| Mpa | Mpa | % | 0℃ J | |||||

| TR(HC) | 640 | 490 | 26 | 117 | ||||

Packing and Recommended Parameters:(DC+)

| Diameter | Spool | Drum | ||||||

| mm/in | Current range(A) | 0.9kg(2 lbs) | 5kg (11 lbs) | 15kg(33 lbs) | 20kg(44 lbs) | 250kg(551 lbs) | 350kg(771lbs) | 400kg(881 lbs) |

| 0.8(0.030) | 50-100 | √ | √ | √ | √ | |||

| 0.9(0.035) | 50-200 | √ | √ | √ | √ | |||

| 1.0(0.040) | 80-250 | √ | √ | √ | √ | √ | ||

| 1.2(0.045) | 100-350 | √ | √ | √ | √ | √ | ||

| 1.4(0.052) | 200-400 | √ | √ | √ | √ | √ | √ | |

| 1.6(1/16) | 250-500 | √ | √ | √ | √ | √ | ||

| 2.0(5/64) | 270-500 | √ | √ | √ | √ | |||

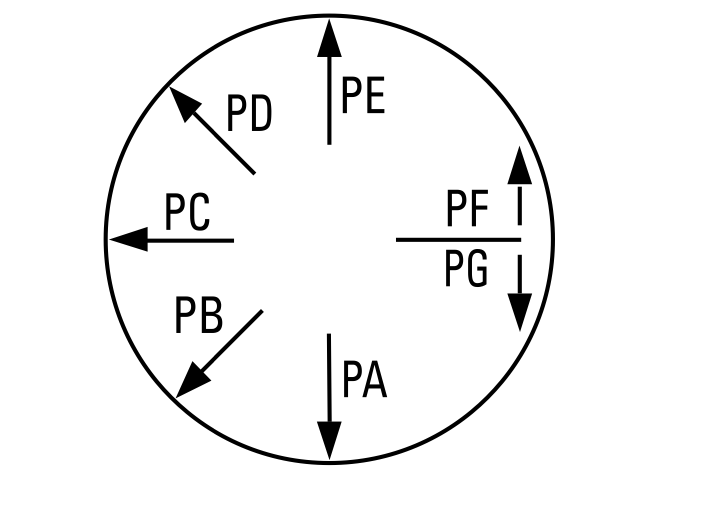

Welding position:

Shielding Gas:

75% ~80%Ar+CO₂

OR:

CO₂

Points for Attention:

1. Gas Flow Rate: 20~25 L/min.

2. Contact Tip-to-Work Distance (CTWD): 15~25 mm.

3. Remove the rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号