SJ-58

Hits:107

ER70S-G

Low Alloy High Strength Steel SJ-58

Specification:AWS A5.18 ER70S-G

JIS Z3312 YGW11

GB/T8110-2008 ER50-G

GB/T8110-2020 G49A0C1S11

Introduction:

Addition of Ti helps stabilize the arc and significantly reduces spatter and fume generation.

Ti also refines the grain structure of the weld bead, greatly enhancing its strength and impact toughness,excellent performance in high-current applications.

Smooth feeding, stable arc, and beautiful weld bead appearance, low spatter,has excellent welding performance.

The deposited metal has good mechanical properties.

Application:

Bridges

Ships

Machinery

Offshore platforms

Pass the certification:

JIS NK

Chemical Composition of Wire %

| C | Mn | Si | P | S | Cu | Ti+Zr | |

| AWS | 0.02-0.15 | 1.40-1.90 | 0.55-1.10 | ≤0.030 | ≤0.030 | ≤0.50 | 0.02-0.30 |

| TR(HC) | 0.07 | 1.55 | 0.83 | 0.012 | 0.011 | 0.14 | 0.23 |

Mechanical Properties of Deposited Metal

| Tensile Strength | Yield Strength | Elongation | Impact Value | |||||

| Mpa | Mpa | % | 0℃ J | |||||

| TR(HC) | 558 | 466 | 27 | 113 | ||||

Packing and Recommended Parameters:(DC+)

| Diameter | Spool | Drum | ||||||

| mm/in | Current range(A) | 0.9kg(2 lbs) | 5kg (11 lbs) | 15kg(33 lbs) | 20kg(44 lbs) | 250kg(551 lbs) | 350kg(771lbs) | 400kg(881 lbs) |

| 0.8(0.030) | 50-100 | √ | √ | √ | √ | |||

| 0.9(0.035) | 50-200 | √ | √ | √ | √ | |||

| 1.0(0.040) | 80-250 | √ | √ | √ | √ | √ | ||

| 1.2(0.045) | 100-350 | √ | √ | √ | √ | √ | ||

| 1.4(0.052) | 200-400 | √ | √ | √ | √ | √ | √ | |

| 1.6(1/16) | 250-500 | √ | √ | √ | √ | √ | ||

| 2.0(5/64) | 270-500 | √ | √ | √ | √ | |||

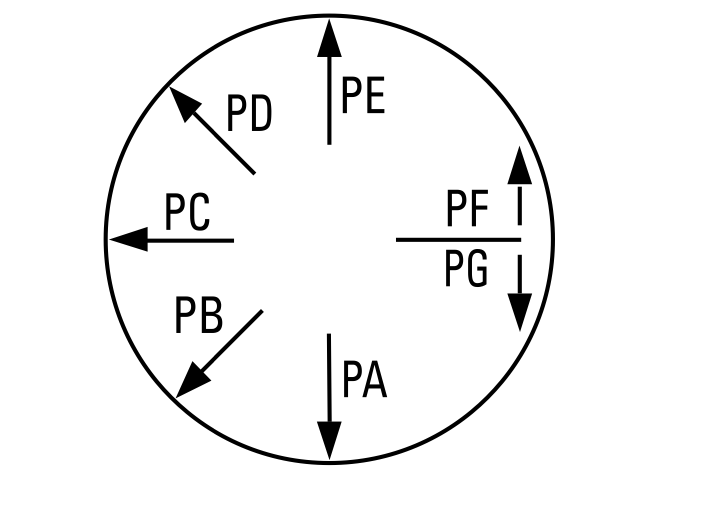

Welding position:

Shielding Gas:

75% ~80%Ar+CO₂

OR:

CO₂

Points for Attention:

1. Gas Flow Rate: 20~25 L/min.

2. Contact Tip-to-Work Distance (CTWD): 15~25 mm.

3. Remove the rust, moisture, oil, dust, and others from the welding area.

苏公网安备 32058202010273号

苏公网安备 32058202010273号